2 HEAVY MOTORS from ITALY to K.S.A.

Sometimes a short distance does not mean that You can take it easy…

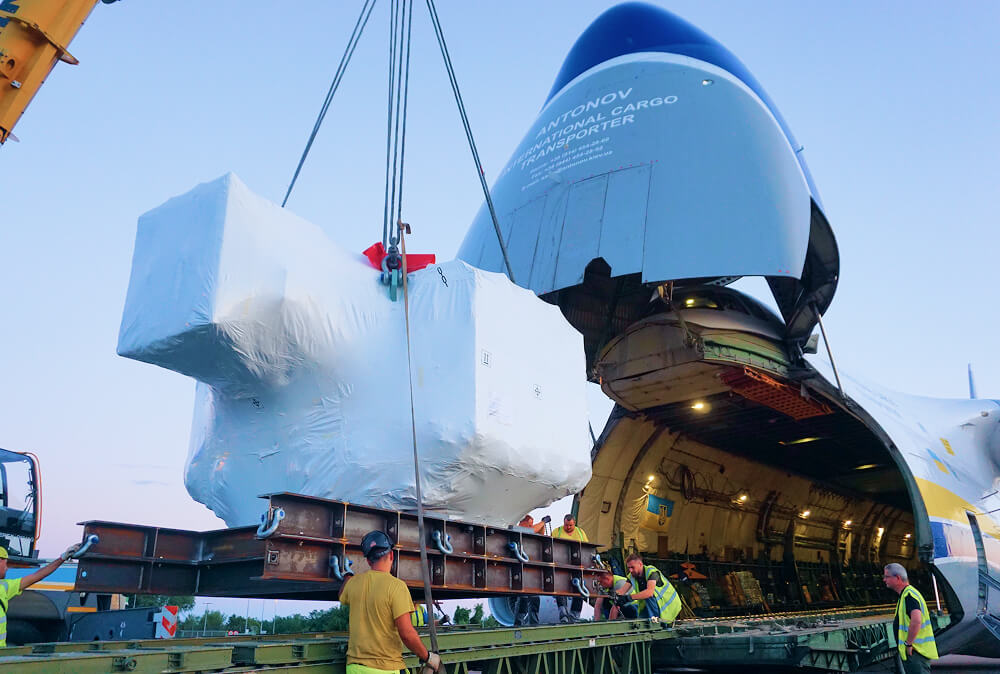

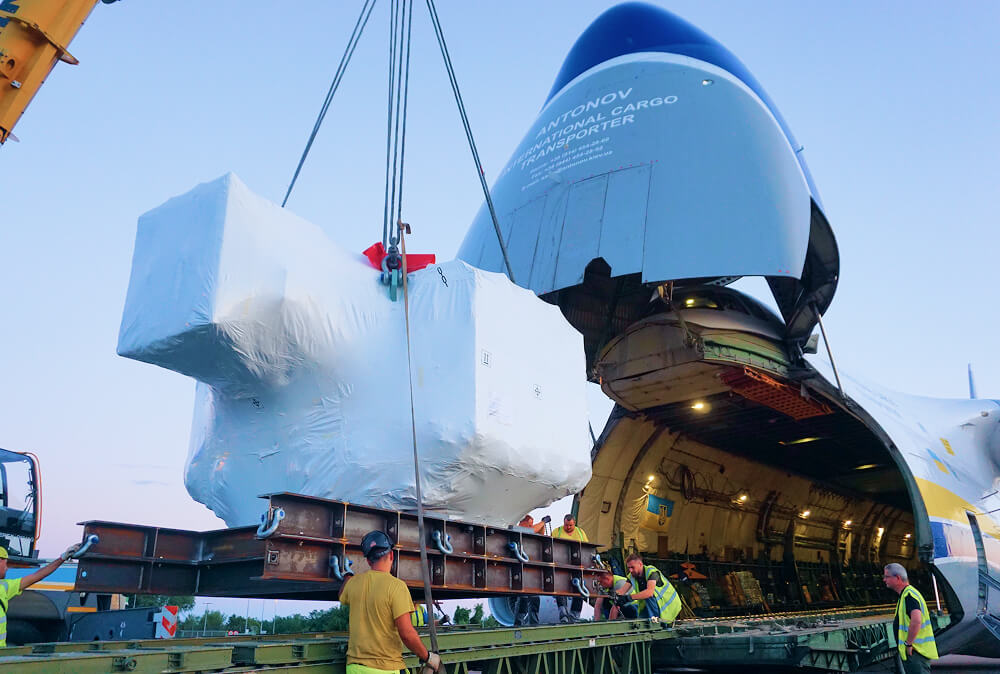

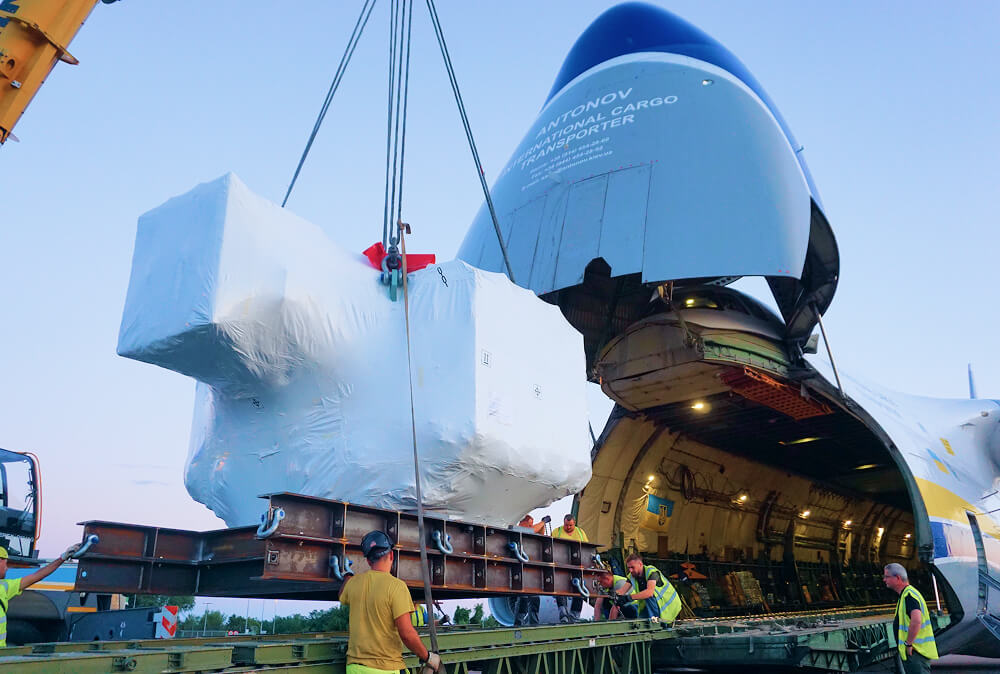

The Challenge: Urgent delivery and aircraft loading of two heavy-lift motors for air freight on The Titan of The Skies

We have been asked to coordinate all logistic activities and on site assistance to execute the delivery of two heavy-lift motors from the production site in Monfalcone to the closest available airport.

After conducting a thorough technical and feasibility assessment, we gave the green light to Ronchi dei Legionari Airport as the optimal departure point. It was the only regional hub capable of handling the Antonov 124-100 and meeting the strict operational requirements for the lift.

Transporting the two massive motors on a short route might seem like a simple job. It wasn’t.

The challenge was clear: deliver both units simultaneously to the designated airport within a narrow loading window for the Antonov 124-100, one of the largest cargo aircraft in the world.

The scope included:

The real obstacle? Navigating the tight safety protocols and securing certified operators approved to work airside—fast. Time wasn’t on our side, but we made it work.

The DCS LIBURNUS PROJECT team took full control on-site, holding a pre-shipment briefing and validating every permit, authorization, and certificate—down to the last bolt.

With zero tolerance for delays, we organized:

Every element was aligned in a few days. Precision wasn’t a luxury—it was the only way to meet the Antonov’s clockwork schedule.

When the Antonov 124-100 touched down at Ronchi dei Legionari, everything was ready before sunrise.

As the aircraft’s iconic nose lifted, we knew the operation was already a success. No delays, no damage, no doubts—just smooth execution that turned into real cost savings for the client.

Once the two motors were secured in the Antonov’s belly, we stepped back and watched her soar into the skies.

“Clear skies and tailwinds, ANTONOV!”

All photos and videos are created by us, showcasing real projects by DCS Liburnus.

We are at your disposal! Contact us for any questions or requests, we are here to help you.