A challenging journey for this large and heavy cargo, covering a straight-line distance of 515 km, required a total journey of over 6,600 km using various transport means and lifting equipment like SPMT trailers, drop deck trailers, overhead cranes, river barges, and sea vessels – nearly 13 times the direct distance!

Given the dimensions and weights, there were few options to transport the heater from the factory to the final destination. Preliminary analysis indicated that the only feasible route to France was by sea. The challenge began with identifying a route that could accommodate such a large load upto an Italian port.

Our technical department contacted various local authorities to check for viability issues and transit regulations and we identified alternative transport scenarios, outlining the pros, cons, and risks.

The heater was planned to be moved via special transport from the factory to the nearest river port.

Given the uncertainty of executing the transport during the dry season we applied for permits for two river ports.

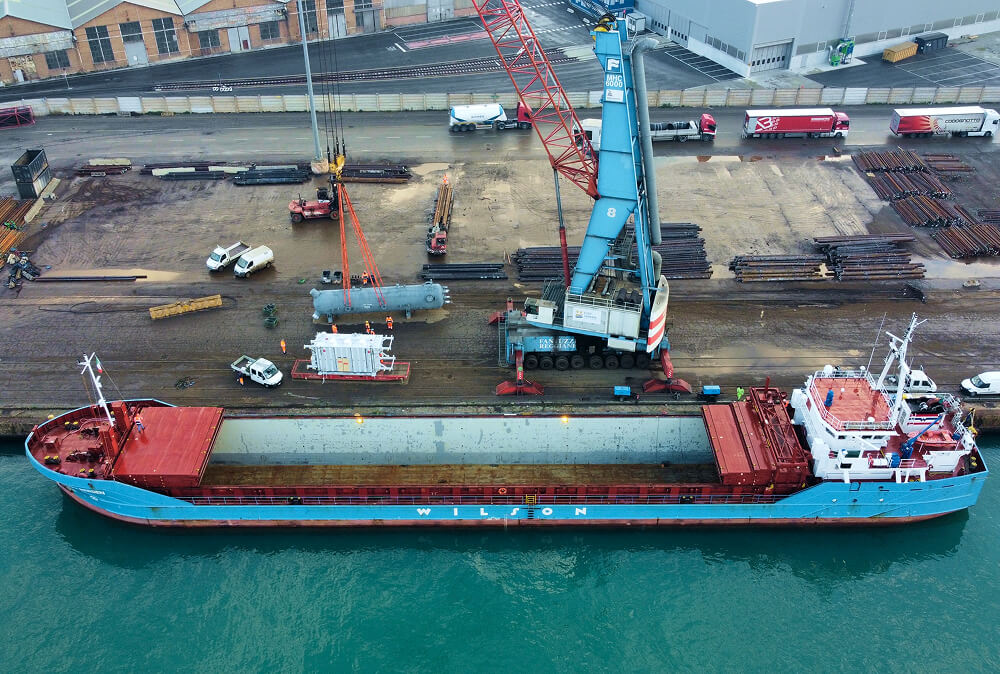

The next step involved loading the heater onto a river barge to be transported to Marghera (IT-30175) for transshipment onto a sea-going vessel.

Our scope included developing the lifting method statement and lashing plan.

Once the manufacturer confirmed all details, we began the application process with all involved authorities to define the transport plan and timings.

We contracted an authorized engineering firm to perform a bridge analysis with static calculations as required by law and we found a time frame without sensitive roadworks, ensuring a smooth transit.

The transit was authorized during the dry period of the Po River, necessitating use of the farthest river port for which we already had permits. This allowed us to avoid shallow waters and ensure the river barge could sail.

Coordinating timings was essential to book the sea vessel from Marghera, avoiding detention and storage charges.

The river barge sailed downstream, reaching Marghera safely and on time. Cranes unloaded the heater, and after the river barge left, the sea vessel loaded the cargo.

Our team provided constant updates and reports, sharing an online “to-do list” with our customer to monitor the documentation and transport progress.

A dedicated team tracked inputs from external sources like providers, authorities, weather conditions, vessels, and ports, making the information easily accessible through our online report management tool.

Crucial waypoints were always attended physically by our personnel to ensure live coverage of operations with photos and videos documenting each phase.

All photos and videos are created by us, showcasing real projects by DCS Liburnus.

We are at your disposal! Contact us for any questions or requests, we are here to help you.